Review of Company B

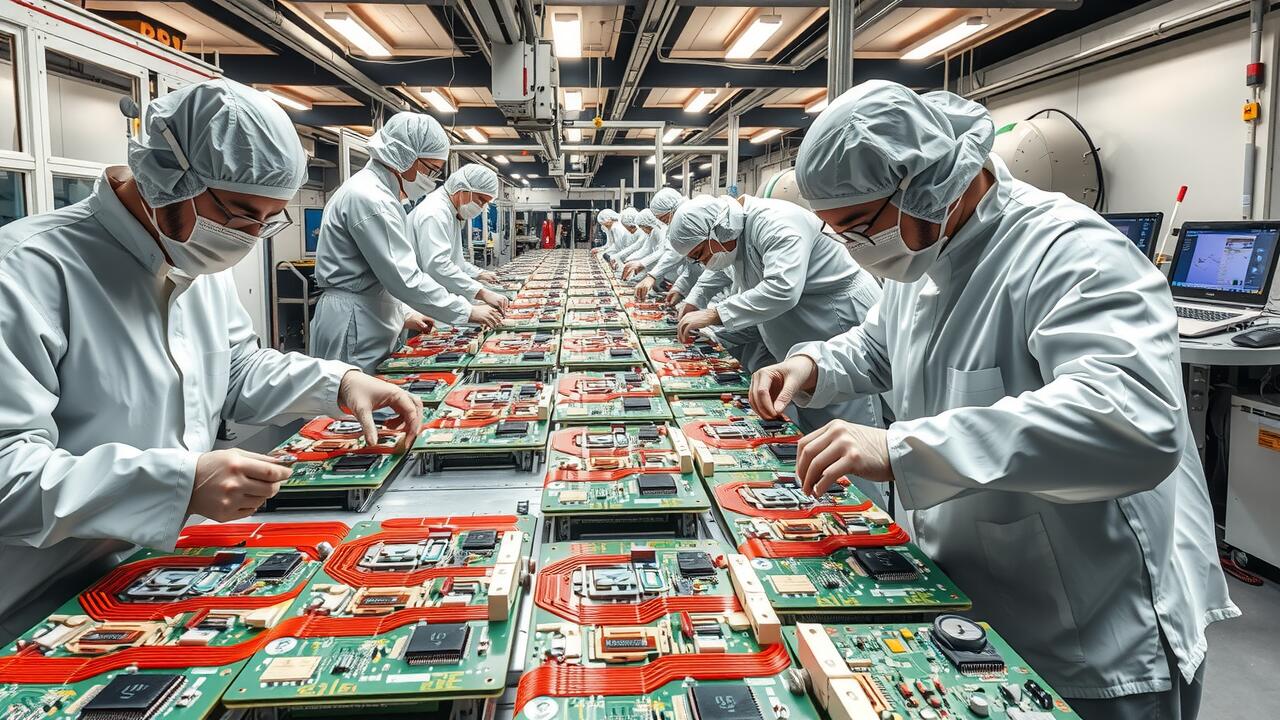

Company B has established itself as a reputable name in the PCB manufacturing industry, known for its commitment to quality and efficiency. Their production processes incorporate the latest technology, which enhances reliability and precision across their product lines. With a diverse array of materials and specifications available, they cater to various sectors including automotive, medical, and consumer electronics. This ability to adapt and specialize has positioned them favorably in a competitive market.

Customer feedback highlights the company’s responsiveness and proactive communication. Many clients appreciate the personalized approach taken by their support teams, fostering long-term relationships and collaboration on design challenges. Case studies reflect successful partnerships where Company B played a pivotal role in accelerating product development timelines. This positive reinforcement from clients underlines Company B's dedication to not just meeting but exceeding customer expectations.

Customer Testimonials and Case Studies

Clients have shared positive feedback about their experiences with Company B, highlighting the efficiency of their manufacturing processes. Many noted prompt responses from the customer service team, which helped in overcoming various production challenges. The accuracy of order fulfillment also garnered praise, ensuring that specifications were met on every project.

Case studies from several industries illustrate Company B's versatility in meeting diverse needs. One case study focused on the aerospace sector, where the company successfully delivered high-reliability PCBs under strict timelines. Another example involved a consumer electronics client that required rapid prototyping, showcasing the firm's ability to adapt and deliver innovative solutions quickly.

Review of Company C

Company C has established itself as a reliable player in the PCB manufacturing sector, offering a solid blend of quality and efficiency. With a focus on innovative processes, this company has refined its production techniques to ensure rapid turnaround times without compromising on the durability or performance of their products.

Their commitment to customer satisfaction is evident in the variety of services they provide, including design support and consultation for custom projects. Clients often praise their responsiveness and flexibility, allowing them to meet specific requirements and adapt to evolving needs. This relational approach has helped Company C build lasting partnerships, elevating its position in a competitive market.

Technology and Capabilities

Company C has established itself as a leader in the PCB manufacturing industry through the implementation of advanced technologies. Their state-of-the-art fabrication processes allow for high-density interconnection and complex circuit designs. Utilizing automated equipment, they can achieve precision in their manufacturing while significantly reducing human error. The integration of computer-aided design (CAD) software further enhances their ability to create intricate layouts efficiently, catering to the diverse needs of their clients.

In addition to cutting-edge manufacturing techniques, their commitment to quality assurance sets them apart. Rigorous testing procedures ensure that all products meet industry standards and customer expectations. The use of intelligent analytics in monitoring production processes enables real-time adjustments, thus enhancing overall operational efficiency. This technological prowess not only streamlines production but also minimizes lead times, ensuring that clients receive their products promptly without compromising on quality.

Comparing Service Offerings Among Top Companies

The landscape of PCB manufacturing is shaped by the varying service offerings of leading companies. Some manufacturers prioritize rapid prototyping, allowing clients to test designs quickly. Others excel in mass production capabilities, ensuring consistent quality at scale. This diversity enables businesses to choose a partner that aligns with their specific needs, whether it be for small batches or large volume runs.

In addition to production capabilities, companies differentiate themselves through design support and customization options. While some firms offer extensive resources for design collaboration, others provide tailored solutions to address unique customer requirements. Understanding these differences is crucial for businesses looking to optimize their PCB projects, as the right choice can streamline processes and enhance final product performance.

Customization and Design Support

Many top PCB manufacturing companies excel in offering customization and design support tailored to the specific needs of their clients. These services often include collaborative design reviews, where engineers work closely with customers to refine layouts and optimize manufacturing processes. Additionally, some companies provide advanced simulation tools that allow clients to visualize the functionality of their designs before production. This proactive approach helps minimize errors and ensures adherence to stringent industry standards.

Furthermore, a key feature of these companies is their ability to accommodate diverse requests, from small batch prototypes to large-scale production runs. Clients frequently have access to a wide range of materials and finishes, allowing them to select options that best suit their application requirements. Strong partnerships with component suppliers also enable faster sourcing and greater flexibility in design modifications. This level of support can significantly enhance product development timelines and overall project success.

FAQS

What are PCB manufacturing companies?

PCB manufacturing companies specialize in producing printed circuit boards (PCBs) that are used in a variety of electronic devices. These companies handle the design, fabrication, and assembly of PCBs to meet specific requirements.

What should I consider when choosing a PCB manufacturer?

When selecting a PCB manufacturer, consider factors such as production capabilities, technology used, customization options, lead times, and customer support. It's also important to review customer testimonials and case studies to gauge their reputation and reliability.

How can I ensure the quality of PCBs produced by a manufacturer?

To ensure quality, look for manufacturers that adhere to industry standards, have certifications such as ISO 9001, and offer quality assurance processes. Reading customer reviews and testimonials can also provide insights into their quality control measures.

What types of customization can I expect from top PCB manufacturers?

Top PCB manufacturers typically offer a range of customization options, including size, shape, layer count, material choice, and specific design features. They may also provide design support to help optimize your PCB for performance and manufacturability.

How do lead times vary among PCB manufacturers?

Lead times can vary based on the complexity of the design, the manufacturer's workload, and the specific services required. It's advisable to discuss and confirm lead times with the manufacturer before placing an order to ensure they meet your project timelines.