Eco-Friendly PCB Manufacturing

The push towards eco-friendly practices in PCB manufacturing has gained significant momentum in recent years. Manufacturers are increasingly adopting sustainable methods that prioritize the use of recyclable materials, minimizing waste and harmful emissions. Innovations in chemical processes, such as the use of water-based etchants and lead-free solders, contribute to a decrease in environmental impact. This commitment not only benefits the planet but also aligns with the growing consumer demand for environmentally responsible products.

In addition to using sustainable materials, companies are integrating energy-efficient technologies into their manufacturing processes. The implementation of renewable energy sources, such as solar and wind power, is becoming prevalent in the production landscape. Advanced techniques, including optimizing workflow and enhancing energy management systems, serve to reduce overall energy consumption. These efforts reflect a broader trend in the electronics industry towards incorporating sustainability at every level of production.

Sustainable Materials and Processes

The push for sustainability in the electronics industry has led to significant advancements in the use of eco-friendly materials for printed circuit boards. New biodegradable substrates are emerging, which reduce environmental impact without compromising performance. Manufacturers are increasingly turning to renewable resources like plant-based resins and recycled materials, which offer effective alternatives to traditional PCB constituents. These innovations not only enhance the ecological footprint of PCB production but also meet the rising consumer demand for greener electronics.

Processes associated with PCB manufacturing are also evolving to become more sustainable. Techniques such as water-based solder mask applications and cleaner etching methods minimize the utilization of harmful chemicals, promoting a safer production environment. Energy-efficient manufacturing processes contribute to lower carbon emissions, supporting the industry's commitment to reducing its overall environmental impact. As awareness grows, more companies are prioritizing these sustainable practices, aligning with global efforts toward sustainability in technology.

High-Temperature PCB Materials

The evolving demands of various industries, especially automotive and aerospace, necessitate the use of high-temperature PCB materials. These materials must withstand extreme conditions without degradation. Commonly used substrates in high-temperature applications include polyimide and modified epoxy, which offer the necessary thermal stability. These materials are engineered to maintain their mechanical and electrical properties even at elevated temperatures, ensuring reliability and performance in critical applications.

As technology progresses, manufacturers are increasingly focused on developing innovative solutions for high-temperature requirements. Advances in material science have led to better hybrid materials that exhibit superior thermal resistance and strength. This focus not only enhances the longevity of PCB assemblies but also accommodates the increasing miniaturization of electronic components. Improved high-temperature materials can help meet specific industry regulations while ensuring optimal functionality in adverse environments.

Meeting Demands of Harsh Environments

The rise in electronic devices operating in extreme conditions has driven the need for high-temperature PCB materials. These materials are specifically designed to withstand fluctuating temperatures, moisture, and chemical exposure. Manufacturers are now utilizing advanced polymers and ceramics to enhance thermal stability and reliability. The incorporation of these materials ensures that PCBs maintain their performance even in severe environments, such as automotive, aerospace, and industrial applications.

As the demand for robust solutions grows, testing and certification processes have also evolved. New standards are emerging to gauge the resilience of PCBs against stress factors commonly found in harsh surroundings. Testing protocols now include assessments for thermal cycling, vibration, and chemical resistance. Manufacturers are investing in R&D to innovate and refine materials while adhering to these enhanced standards. This focus not only improves reliability but also promotes safety in applications where failure is not an option.

Automation in PCB Assembly

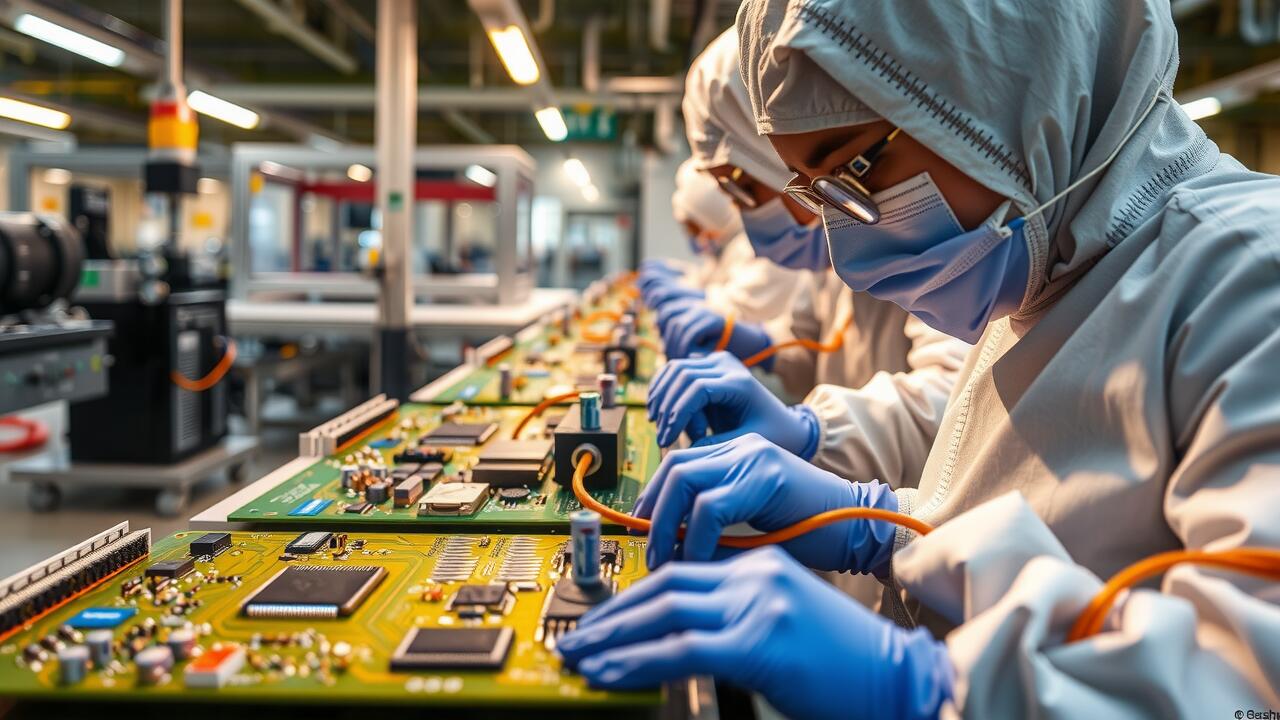

The integration of automation within PCB assembly processes has significantly transformed the manufacturing landscape. Automated systems streamline production lines, improving accuracy while minimizing human error. This shift allows manufacturers to achieve higher throughput rates, which are essential in meeting the growing demand for faster production cycles. Robotics and advanced machinery are increasingly capable of performing complex tasks with precision, completely redefining traditional assembly methods.

Moreover, automation reduces operational costs by enhancing labor efficiency. With many processes being handled by machines, companies can allocate their workforce to require less repetitive and labor-intensive tasks. This balance between human oversight and machine efficacy not only helps in maintaining quality control but also fosters innovation within the industry. As technology evolves, the trend towards more sophisticated automated systems is likely to continue, further optimizing PCB assembly operations.

Increasing Efficiency and Reducing Costs

Advancements in automation have transformed PCB assembly processes, enhancing production efficiency while minimizing costs. With the integration of robotics and AI-driven systems, manufacturers can streamline repetitive tasks, ensuring consistent quality and reducing the potential for human error. These automated setups not only expedite the assembly line but also allow for greater precision, essential for meeting the pressurized demands of current technology markets.

Moreover, digital tools and software solutions are playing a significant role in optimizing workflow and supply chain logistics. By analyzing data in real time, manufacturers can identify bottlenecks and adjust operations accordingly. This proactive approach leads to effective inventory management and waste reduction, contributing to lower overall production costs while maintaining high-quality standards in PCB manufacturing.

FAQS

What are eco-friendly PCB manufacturing techniques?

Eco-friendly PCB manufacturing techniques focus on reducing environmental impact through the use of sustainable materials and processes that minimize waste and pollution during production.

What sustainable materials are used in PCB manufacturing?

Sustainable materials in PCB manufacturing include biodegradable substrates, lead-free solder, and recycled copper, which aim to reduce the ecological footprint of the production process.

Why are high-temperature PCB materials important?

High-temperature PCB materials are crucial for applications in harsh environments, such as aerospace and automotive industries, where traditional materials may fail due to extreme temperature fluctuations.

How does automation improve PCB assembly?

Automation in PCB assembly enhances efficiency and reduces costs by streamlining production processes, increasing accuracy, and minimizing human error, leading to faster turnaround times.

What challenges do PCB manufacturers face when adapting to new innovations?

Challenges include the need for investment in new technology, training for staff, and ensuring compatibility with existing systems, as well as navigating regulatory standards for materials and processes.